You can use different technologies to mark metals, including punching, molding, labeling, and micro-percussion. However, laser marking has revolutionized this process like nothing else before, becoming the most convenient and widely used professional method.

It is not easy to have more information about laser marking for metal but let’s try to summarize the main questions.

What’s the best laser source for marking metal?

Fiber laser sources are the best and most innovative metal marking laser technology. They’re ideal for precision marking, micro-processing and cutting any metal, alloy, painted metals, and metals with a treated surface (e.g. anodized aluminum).

Fiber laser technology has marked a milestone in laser beam generation. Many optical and mechanical components, which caused failures and instability, have been replaced by one active fiber optic coil. The fiber laser is expected to ensure over 100,000 marking hours thanks to single-emitter diodes and the fully integrated construction of the optical

part.

Infrared (IR) beams are the most versatile for laser processes. IR beams are outside the visible spectrum for the human eye.

THE ADVANTAGES OF FIBER LASER MARKING

- No contact

- High speed

- High quality

- Indelible marking

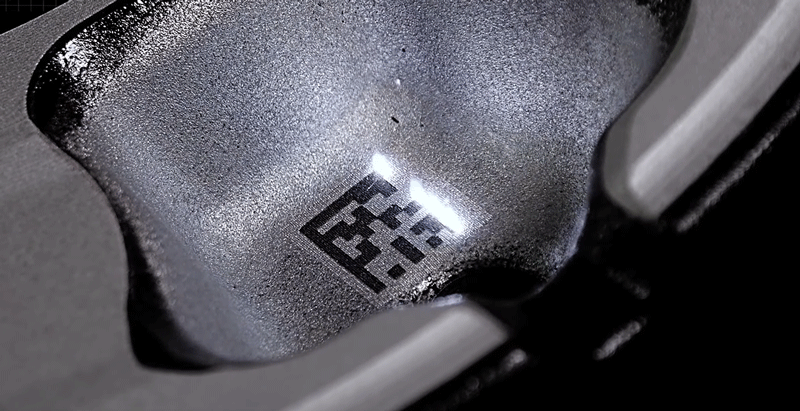

- Easy-to-use data matrix codes

- Wide range of markable materials

Can laser engrave any metal?

Laser can engrave any metal or alloy, including steel, aluminum, copper, gold, brass and nickel. However, not all materials react in the same way. Moreover, some materials require specific processes.

Laser marking steel falls within two categories: surface marking and etched marking

SURFACE MARKING

Metals are marked so that the propagated light generates

white markings or a thin oxide layer, resulting in black

markings.

- White marking is obtained quickly without altering the material’s surface.

- High-contrast black marking without altering the material’s surface and/or its roughness.

ETCHED MARKING

The material is removed revealing the etching.

- Less regular surface with protruding and recessed parts (based on the material used).

- Greater resistance even to mechanical abrasions.

Is laser marking indelible?

Laser marking is indelible. Laser allows you to identify and trace products with a high resolution finish, ensuring longlasting markings that are also resistant to acids, chemicals and corrosion. In brief, to delete laser marking you need to remove the marked surface mechanically.

Can I use color laser marking?

Yes, you can. However, you must always evaluate the type of metal first.

Steel and titanium are most suitable for obtaining vibrant colors. These materials can undergo “annealing”.

The laser heats the material’s surface, chemically changing it and generating oxide.

By controlling the energy from the laser, you can add different temperatures, thus forming different oxide layers. Each layer is a color.

you can obtain white markings, black markings, or colored markings by controlling this process

and using always the same laser without engraving the material.

Laser is an extremely fast and flexible tool. Laser marking can be made in less than one second.

The factors that can determine the length of the process are:

- Dimensions of the object to be marked

- Engraving depth

- Laser Power