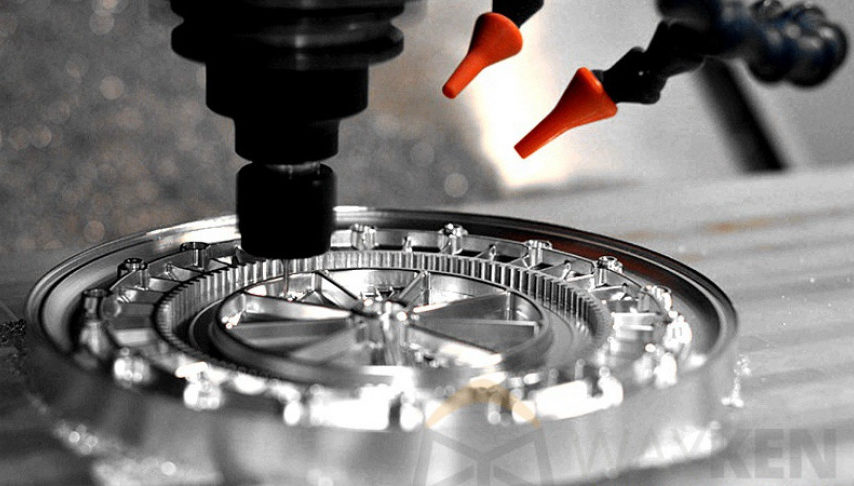

There are some CNC machine shops near me which are producing some absolutely phenomenal products for their clients. I once worked in a similar place and the difference between then and now, with regards to what they are producing is huge. CNC machining is the art of using a computer to create parts and pieces of equipment which can be used in the manufacturing process and what many don’t realize is that this particular process has completely revolutionized the world of manufacturing.

There are many ways in which the world CNC machining has done this, which I want to touch upon today.

Lower Cost For Businesses

If we look into the specific production of parts for larger machines, we can see that CNC machining is responsible for massive cost savings to so many businesses. Once upon a time an entire machine on the production line may have had to be replaced because of a certain number of parts which had gone wrong, this is not the case any more. Owing to the automation of CNC machining, parts can easily be designed and created in no time at all, to save the company money and get their production line back on track.

Faster Production

A complex product would always have put pressure on a manufacturer and it also would have come at great cost based on the expertise, the difficulty and the time it would have taken to produce. Using production machining however even a highly complex product can be created at speed and that means lower cost and a large scale of production.

Lower Wastage

The key to why CNC machining is so successful comes down to the precision which it offers, and there are a number of consequential benefits which this brings. One particular benefit which that precision is able to deliver is the reduction in waste. The computer driven machine will cut perfectly and it will not make a single mistake. This contributes towards less waste which therefore means less money lost as a result, and greener credentials for the business which is creating the product.

Safety

Something which many fail to recognize when discussing the use of computers over humans, is that it often increases the safety of our staff. In the case of production like this, anything which involves the cutting of metals using high powered cutting devices will always present a danger. Thanks to the full automation of a CNC machine, the level of risk is completely removed.

Same Result Every Time

Manual machining is always going to provide imperfect results which means that the product will be ever so slightly different each time. This is now a thing of the past thanks to CNC machining which is able to repeatedly deliver perfect results thanks to the high level of precision and the specific design which it works from.

This tech advancement has been one of the most impactful that we have seen in manufacturing in the last 50 years.