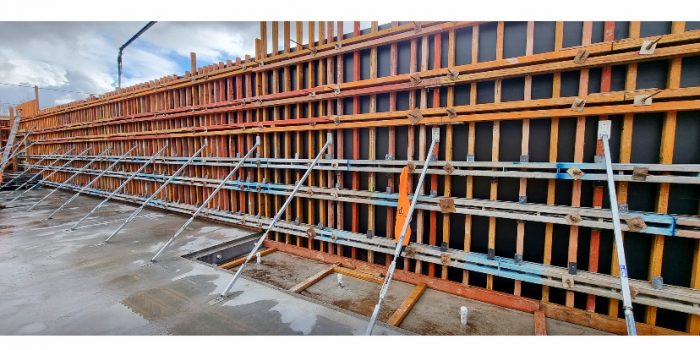

Simply put, formwork is the mold utilized in the construction of a structure. When concrete is poured into these molds, it gives the structure a shape. Formwork is available in a variety of sizes and shapes. When it comes to any type of construction, formwork is crucial. As a result, it’s critical to hire steel formwork in Melbourne, such as Cassa form, because it improves the building quality and layout of your structure. Timber, plywood, steel, and aluminum formwork are the most common types of formwork. Formwork is the foundation for good construction.

What is Steel Formwork?

The term “formwork” refers to the material used to mold or shape concrete buildings prior to curing. It can be permanent, such as lost formwork cast into slabs, or temporary, such as either side of in-situ walls. For modular aluminum-type systems, temporary formwork consists of plastic sheets or plywood braced by traditional timbers. Formwork liners are used depending on the type of formwork system used and the level of polish necessary to improve the concrete finish. Shoring or falsework, which is made composed of aluminum, timber, or steel components, supports the formwork. Given the number of equipment required and the duration of shorter projects, formwork hire may be a viable option to purchase.

What Is Formwork?

Here Are Five Things To Think About Before Hiring Formwork Systems

- Check your construction requirements:- You should double-check the construction standards ahead of time. You’ll need to rent a formwork system that satisfies your specs as well as your mechanical needs. They must have the formwork capability required for concrete structures. You should request that they assess the situation and recommend the appropriate formwork to meet your needs.

- Cost estimation:- Formwork systems must be contacted early in the construction process. It will assist you in discussing all of the details and obtaining a quote for the same. Budgeting for these costs is necessary, as is comparing quotations from various formwork systems. The formwork supplier can provide you with a bid that includes all of the project’s requirements as well as a timetable. Field support, freight, tools, and labor requirements must all be included in the estimate.

- Professional services:- Engineering services are provided by a competent formwork business, as well as assistance with design adjustments to save project costs. Formwork systems will provide erection plans that meet your specifications. It will secure the project’s success while also lowering costs.

- Check for reviews:- You must read the reviews to pick the best formwork system. The reviews could be published on their website or on their social media profiles. It provides an accurate picture of the firm’s service quality. Furthermore, people provide unbiased reviews that will assist you in forming an opinion.

- Go for a local formwork system:- After you’ve completed your design specifications, there will be a slew of formwork companies to choose from. You must make an informed pick from among all of these options. Start by searching for formwork systems in your area on Google. After that, you can submit a request on Instagram or Facebook’s local community page and search local directories for formwork systems. You might also ask your neighbors, acquaintances, or family members for recommendations.

Conclusion:- Formwork is the foundation for a high-quality building. As a result, you must carefully select the steel formwork system. Find a few options, evaluate their services, request a quote, and then decide which one best meets your needs.