In today’s market, every industry intends to manufacture a low volume application. The PCB assembly process involves the same concept: to produce small volume boards to meet the clients’ requirements. Of course, the desire of industries will differ from one another. Understanding the aim of Low volume PCB assembly is to enhance the board’s quality and iron out any issues that come. Thus, both DFM (design for manufacturing) and DFT (design for testing) are used while manufacturing it. All because of acquiring the issue easily. Before you head to perform any mass production, it is a must to optimize. No matter what, Low volume PCB assembly is the ultimate solution to optimize the PCB’s integrity. At the same time, it is a cost-effective solution as well. Undoubtedly, using low volume PCB assembly is an advantageous option that you should know for sure. Therefore, to learn more about it, look at the below article.

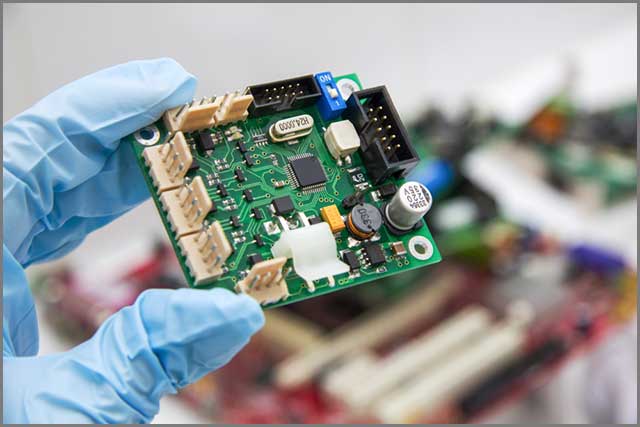

Low Volume PCB Assembly

The low volume PCB assembly aims to manufacture small volumes. Notably, the implementation of PCB includes board design, particle accumulation, and assembly; these three are the basic things. No matter the type of PCB assemblies, such as low volume or high volume, the testing design or DFT are the two essential operations that will help you enhance maximum profit that will come within your budget. No matter what, the PCB design might change based on your requirements and application. PCB assembly compiles a relatively insignificant printed circuit board or PCB when it comes to the low volume. The important thing is that this type of board will include both DFM and DFT checking. The manufacturing of low volume PCB assembly intends to increase the number of boards. Using low volume PCB assembly is beneficial in many ways and will allow you to obtain various advantages for sure easily. Here are the benefits you should know.

Advantage of Low Volume PCB Assembly

You can understand that the assembly defines the small volume circuit board assemblies even by the name. The actual quantity of the assembly is from 25- 1000 or sometimes 5000. No matter what, the small volume assemblies are best for OEMs. Specifically, it is manufactured for the new products. With the help of the small assembly design, let you understand the problems that come in. Along with that, the prototype of PCB will make the customers acquire the final design. At the same time, you can easily create a better design based on the requirements of the products. Importantly, if you aim to run the product for the long term, it is essential. The main thing you should notice in the low volume PCB assembly is its small quantity. Even if it is small, that will offer better results. That is why most industries use the low volume PCB assembly in various applications.

How best is low volume PCB assembly?

Be it small production or huge production range, almost all PCB manufacturers will apply the same testing and troubleshooting practices. Therefore, any components that want to be replaced or repaired in Low volume PCB assembly can be easily obtained. Likewise, it will offer a lot of benefits. Hence, you can also avoid spending a lot of money when it comes to the replacement or repair.