Before mentioning the importance of prototype plastic extrusions, it is imperative to know what extrusion prototyping is. Extrusion is mainly referred to as those specific parts which have a definitive cross-sectional profile. These extrusions are used on a large scale but before using these extrusions, generating prototypes beforehand to test these extrusions acts like a plus point wherein if there is any damage or any changes, those can be done on the extrusions beforehand in order to avoid any future problems. This is one of the reasons why manufacturers require prototype extrusions to figure out damages and defects and make changes on them so that they can be used efficiently and effectively on a large scale.

Why choose prototype plastic extrusion?

Extrusion prototyping is known to be one of the most highly economical methods of manufacturing where access panels to some post-machining fixing joints can be added. This production method makes sure that when these extrusions are introduced in the market, they avoid future problems or complaints which can affect the business in the negative way all together. This production method has also proven to be cheaper as well as faster with their efficiency leading to creating extrusions prototypes. These extrusions prototyping is mainly used for manufacturing plastic and even aluminium products which includes pipes, conduits and even window frames.

The above-mentioned reasons tell us why prototype extrusion is important. On top of it in order to explain or understand the process of prototype extrusion examples of plastic and aluminium can be used.

Extrusion Prototyping with Plastic and Aluminium

One of the major questions which arises in the mindsets of individuals is what can be produced using extrusion prototyping services. There are multiple options and things which can be produced using extrusion prototyping such as Aluminium and plastic on a large scale if you are working with experienced and talented service providers.

Plastic:

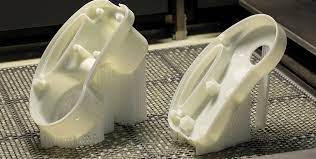

In the case of Plastic, the most widely used material in this scenario is PVC. In the whole process of plastic extrusion, the first step requires the melting of plastic which can then be shaped into a variety of continuous profiles which can further be changed or shaped into various lengths and sizes. Plastic extrusion is one of the most beneficial techniques which can help the service provider in producing a wide variety of products in different styles, different shapes and sizes using plastic and materials which involve PVC, PS, PP, ABS, PC and even PMMA.

Aluminium:

Now in the case of Aluminium, wire eroding is essential and beneficial only if the part required from aluminium is 600mm in length. In the case of Aluminium, the whole process of extrusion is slow and requires time but the end result of extrusion aluminium will be worth the wait as the wire which is produced after the whole process involves proper details with exemplary service finishing. Now in the case when the whole process is longer than usual and results to be simple then there is a possibility in this scenario to CNC the prototype up to lengths of 1 meter long. But this step proves to be extremely tricky and very sensitive to geometry and moreover the wall section may or may not be suitable for all cases. With this whole process of extrusion of Aluminium, the other good options which can be created using this technique can include tubing, sections, rods, and even co-extruded parts.

One can hire professionals and experts to make sure that the extrusion prototype can be done effectively and efficiently. Also, these are the reasons which tell us the importance of plastic prototype extrusions.