Rapid electronics technology evolution has become the demand of current times because people never settle with the existing technology for a long time. In order to meet their expectations and stay in the competition, we need ATE (Automatic testing Equipment) with high density and low power to get fast results. Consequently, the demand for semiconductor test equipment has increased. We need them to build a future world where technologies like deep learning, artificial intelligence and IoT are fully developed. Even the flagship digital electronics like smartphones and IE integrated speakers cannot survive for a long time if their updated version is not available in the market. Let’s elaborate on semiconductor test equipment in detail.

Understanding semiconductor test equipment

First of all, clarify one thing in your mind that semiconductor testing equipment, automated test equipment (ATE) and integrated circuit (IC) are the same. These are just different terms so don’t get confused. The entire system is made up of semiconductor material that can be:-

- Silicon (Si),

- Germanium (Ge)

- Gallium arsenide (GaAs)

Semiconductors lie between insulators and conductors of electricity. To protect the equipment from high current, transient voltage suppressor diode are used. Now the next question is, why do we need semiconductors instead of good conductors in electronics. Scroll down for your answer.

Why semiconductors are essential for the testing system?

Despite the poor electric current supply potential of semiconductors like silicon and germanium, they are the primary preferences. Not just one but there are multiple reasons behind choosing semiconductor material in testing equipment i.e.

- They consume substantially less amount of energy as compared to the conductor materials.

- They easily fit in the least possible area.

- Semiconductors are compatible with all types of operational activities like mathematical operations, oscillation and amplification.

In the integrated testing industry, you will find two types of semiconductor devices including:-

- Low Voltage Pin Electronics

Both have different significances that we are going to explain n the article below.

Elaborating on high and low voltage pin electronics

High voltage semiconductors

We need high voltage semiconductors in the megawatt power systems getting developed with the objective of power rating improvement. High voltage semiconductors are meant for translating low voltage signals to a sufficient level where high voltage applications can get stable power. Transmission and distribution, traction and industrial applications are the three major areas where we need high voltage semiconductors. In simple words, manufacturers need these semiconductors to develop appliances certified with the highest star rating out of 5. Below are some advantages you need to consider:-

- High reliability of endurance in both normal and faulty circumstances

- High-level robustness

- Better control

- Less depreciation

Low voltage semiconductors

Low power pin electronics for testing are playing a significant role in developing nanotechnology. These semiconductors are useful in developing highly efficient compact devices that can be high-performance computing systems and wireless devices. With continuous advancements, devices with very large scale integration potential are now available to use. They are capable of containing hundreds of millions of transistors. In order to prevent power dissipation during the testing phase, we need god quality low voltage semiconductors.

Very Large Scale Integration in low voltage semiconductors

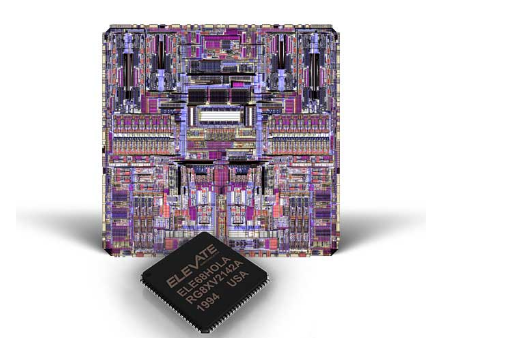

Very Large Scale Integration (VLSI) is a process of combining millions of transistors on a single chipset. We need this technology in memory chips and microprocessors to increase their multifunctioning potential. VLSI technology is a revolutionary step in developing flagship computation devices and smartphones. With continuous improvements, the sizes of devices are getting more compact along with higher potential upgrades.

Different types of semiconductor components we need in integrated testing

This is the era of multifunctional compact technologies demand, so you need to develop complex large scale integration (LSI) circuits. It is possible with different types of solid-state devices integration including:-

- Thyristor

- Gate turn-off thyristor

- MOS-controlled thyristor

- Integrated gate-commutated thyristor

- Diode

- Silicon-controlled rectifier

- Triac

- Power MOSFET

- Bipolar junction transistor

- Insulated-gate bipolar transistor

Very large scale integration technology advancement in low voltage semiconductors is bringing revolutionary transformations in the microprocessors industry. Our expectations from technologies like IoT, artificial intelligence and machine learning are increasing day by day. Without integrated testing pin electronics, it is not possible to achieve the objective.